TF Anti-sway Bar from LaVerne Downey

was seeking to lessen cornering body roll in the TF and had mentioned it

as one of my future projects in a BBS post. A big thanks to Dan Craig

who offered up a used MGB 5/8" bar and all the fittings including new

urethane eye bushings at no charge. This isn't the first time I have been

given needed parts from fellow MGers and I have done so for others myself.

We are truly a unique generous group. A little cleaning of the bar and some

black paint and she looked like new. When trying to fit the bushing to the

ends of the sway bar, I had no success with hand force, pliers or even a

bench vice. In the end I found that you can place the bushings in by

hand if you place them in boiling water for approximately 10 minutes. Remove

them and quickly force them in by hand. If you don't succeed on the

first try, place them back into the boiling water for another 10 minutes or

so. You must work fast as the urethane will stiffen back up fairly quick

after removal from the water. Be careful, It is boiling water after all!

The used lower control arms had some oval issues on the out board end so I

was faced with three choices.

1. Weld around the opening and re drill the hole.

2. Weld in a trapezoid piece into the stock TF arm and drill the hole for

the sway bar.

3. Buy a new set of MGB arms.

In as much as I needed some bits from Moss anyway, I chose to order new arms

and forego the challenge of rebuilding the arms. I also purchased new links

as the rubber in the supplied ones were well aged.

For those not familiar with the MGB arm and spring pan, I have provided a

photo of both along side of the TD/TF arm and pan so you may see the

differences.

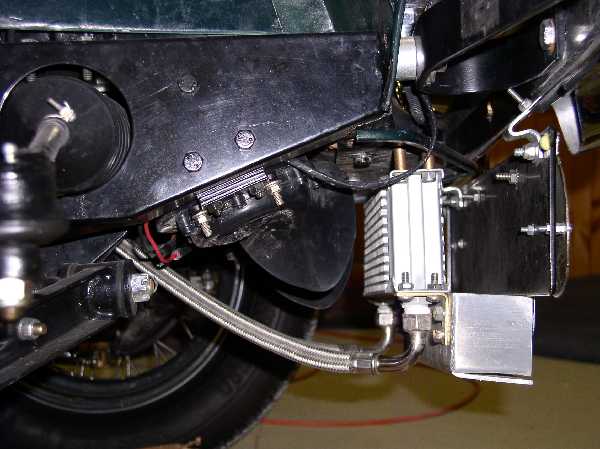

The TF provides some challenges because of the horns being mounted between

the dumb irons. In addition I have mounted an oil cooler under the front

pan. After looking at John Progess' and John James mounting with the

shortened links I decided I would see if the standard "over the tie rod"

method could be accommodated. After removing the horns I found that I could

use the forward horn mounting hole for the rear of the sway bar bracket and

go over the tie rods. This position provides ample clearance for the tie rod

ends in all sprung and un sprung positions as well as clearance from full

track to track on the steering rack. After mounting the bar the next issues

was placement of the horns. I found that the left horn could be mounted in

its original position by mounting it under the dumb iron. The right hand

side horn had to be moved closer to center because of interference issues

with the brass end of the steering rack. I simply used some 1/4" bar stock

and mounted it to the original dumb bar holes and mounted the horn to the

other end. I also had to add some washers closest to the engine side to

effect a little camber to gain the necessary clearance. Due to the location

of the horns it was necessary to mount the sway bar locating clamps on the

out side of the body bushing brackets. I would suspect that right hand drive

cars would have to reverse the process. The horns set no lower than the sump

and in my case are sheilded by the oil cooler.

A word of caution for TFers that might attempt this installation. My TF had

been "nosed" into a rock in the Colorado river many many years before my

ownership. The dumb irons had been cobbled back together and only one Lucas

horn was on the car under the bonnet TD style when I bought it. I fabricated

some new dumb irons and the horns are a Chinese Moss replacement. This said,

my mounting holes may or may not be in the same location as original and you

may or may not be able to mount your horns as I have done.

*************************************************************************************************

Attached below is the series of images from LaVerne. Email

questions can be sent to LaVerne by clicking

HERE.