Ttalk.info

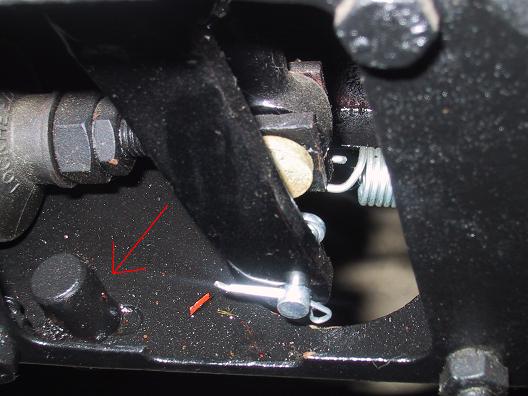

TD Clutch Pedal Stop location. Image reproduced with permission of Evan Ford.

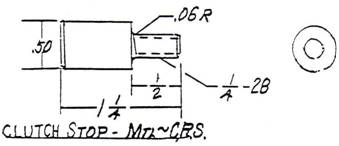

And below, with his permission, are the details from David DuBois

TD Clutch Pedal Stop Bolt

Something interesting happened on the way to the forum (actually while looking up information for a member named Richard, who posted a question on the MG Cars Enthusiasts’ Club T Series TD-TF bulletin board a number of years ago, about excessive pedal travel in his TD in regards to the clutch pedal stop in the TD/TF). My first stop was the T series Handbook, published by the New England Register, the pedal stop on the early TDs (TD/0251 through TD/22250). According to that source, the stop for travel of the clutch pedal was accomplished by the cable that operated the clutch. Starting with TD22251 through the TFs, the cable was abandoned and a rod linkage was used to operate the clutch. At this point, a clutch pedal stop bolt was added to the bottom of the pedal box in the cars. The cable stop and the clutch pedal stop bolt effectively stops any further travel of the throw out bearing against the thrust plate on the clutch pressure plate beyond the point where the clutch disk is released and the prevention of possible damage to the clutch throw out bearing due to over travel. Over time, many of the early cars that had originally been equipped with the cable were converted to the clutch rod linkage, but since there was no mention anywhere about the clutch stop bolt, said bolt was not added to these cars (to my knowledge, the stop bolts are not carried by any of the parts suppliers for the T series cars) . Also the pedal stop bolt in a number of the later TDs and in the TFs were undoubtedly lost or didn't get reinstalled during repair or restoration.

Fast forward a number of years and Mike O'Connor of O'Connor classics in California wrote an article in response to the breakage/bending of the main clutch rod in TD as a result of interference with the web of the clutch lever on the side of the sump. Mike's cure for this problem was to grind the web of the clutch lever at an angle so that the clutch rod was no longer bothered by this web. Also somewhere around that time frame, two other gentlemen in California wrote a seemingly unrelated article about, among other things, the missing clutch stop bolt and how to make one and install it in the early cars that never had one. Both of these articles reside in my great file of things MG, having been read by me and filed for future reference (such as when someone like Richard asks the question about excessive clutch pedal travel). In particular, Mike O'Connor's article piqued my curiosity as to why I had never had a problem with clutch rod breakage or bending even though the web in the clutch lever on our TD had never been modified. My curiosity was piqued, but not sufficiently to make me explore the reason the clutch rod/clutch lever in our TD had not had any problem and so nothing was looked into or done other than check that the clutch stop bolt was in fact installed in our TD. Because of Richard's question, I dug out the two aforementioned articles and made copies to send to Richard and it was then that the penny finally dropped - the missing clutch stop bolt was the reason for the need of Mike O'Connor's modification to the clutch lever on the early TD. I also realized that I had never heard of a clutch rod being broken on a TF. Serendipity is a wonderful thing.

The following is an article by Stuart Lock and Bill Phy, titled, A Stop To Go With It

After Stuart installed the new adjustable clutch link and properly adjusting

it for correct release, he found that the pedal would travel to the floor.

This was accompanied by a loud grinding sound indicating all was not

right. Stuart found that when

the early TD's TD/0251-TD/22250 with cable actuated clutch had the cable

removed and replaced with a rod actuated

linkage had no pedal stop.

When they were converted to rod actuation some "mechanics failed to

install a stop and relied on the linkage binding to prevent over-travel.

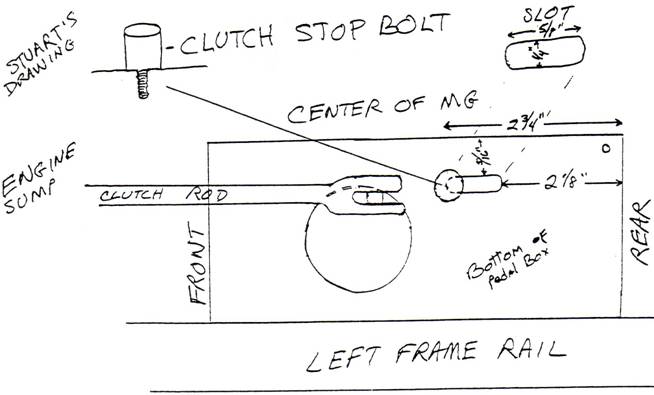

The late TD & TF stop pictured below, when positioned as shown in the

drawing below will prevent

over-travel resulting in that dreaded "throw-out bearing eating the clutch

fingers", grinding sound. To

prevent clutch damage it would be wise to install the stop in your TD if the

clutch cable mechanism has been replaced with the later rod linkage.

From underneath the pedal box, make a slot 1/4”X 5/8" in the bottom

of the pedal box about one inch

behind the clutch rod (see Stuart’s drawing below or look at a Late TD or a

TF, one that has the body off, preferable.

Take off your pedal box access side panel and install the stop from

inside the box. Stick the

threaded portion down through the slot and secure it with a nut and lock

washer from underneath. Your new clutch stop bolt should be set such that

the clutch is completely disengaged, but does not over travel the position

of full disengagement. Note: Clutch stop bolt is no longer available.

Make one or have one made. (See Bill Phy's drawing below).

The following pages have background information taken from the ‘T’ Series

Handbook, published by the New England MG ‘T’ Register and the workshop

manual for the TD.

From the ‘T’

Series Handbook:

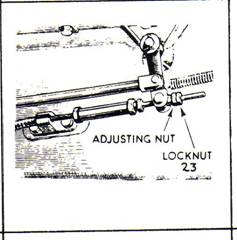

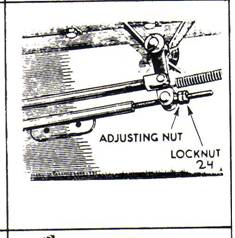

TD 22251

(Nov. 20, 1952): Commencing

with this chassis and engine number XPAG/TD2/22717 the original cable

operated clutch linkage (fig. 23) was replaced by a simpler rod (fig. 24),

and a stop

bolt was added to the pedal bracket on the chassis to limit clutch pedal

travel.

Fig. 23

Fig. 24

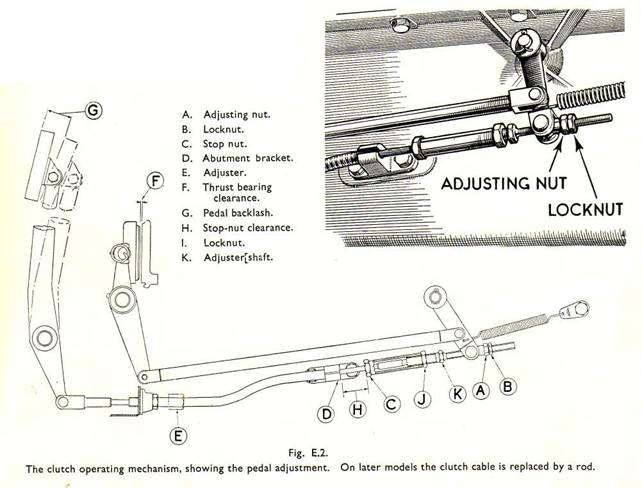

From the TD Workshop Manual

Section E.1

RUNNING ADJUSTMENTS

The only adjustment necessary throughout the life of the driven plate

facings is to restore periodically the free movement of the clutch pedal

(i.e. movement of the pedal before the release bearing comes into contact

with the release lever plate and commences to withdraw the clutch).

As the driven plate facings wear, the free movement of the pedal will

gradually decrease, eventually preventing the clutch fully engaging and

permitting too great a movement on withdrawal.

The minimum clearance at "F" (see Fig. E.2) between the withdrawal lever

plate and the face of the thrust bearing is 1/16 in. (1.59 mm.), which

gives a free pedal movement "G" of 3/4 in. or 19 mm. at the clutch pedal

which should always be maintained.

When the clutch pedal free movement becomes less than this, it is essential

to make use of the adjustment provided.

This consists of an adjusting nut "A" and locknut "B" at the forward

end of the clutch operating cable.

Care should be taken to tighten up the locknut "B" after adjustment.

In addition, care must be taken to see that the pedal travel is not

excessive, as this will apply an excessive load on the carbon thrust block,

leading to its early failure.

There should be approximately 1 1/8 in. or 29 mm. clearance at "H" between

the stop nut "C" and the abutment bracket "D" when the pedal is lightly held

with the carbon block in contact with the thrust ring by pushing lightly on

the clutch pedal by hand. To

obtain adjustment, grip the nut "C" and slack off the locknut "J" ; grip the

adjuster shaft hexagon "K" and adjust the stop nut "C” to the required

position. Re-tighten the

locknut "J" after adjustment.

Need for this adjustment will be indicated when there is a tendency for the

clutch not to free when the pedal is fully depressed.

Adjuster "E" is only for the initial adjusting of the outer cable length to

give the correct flexibility between the pedal box and floating engine, and

should require no subsequent setting.

Section E.10

INTRODUCTION OF A CLUCH CONTROL ROD

Commencing at Chassis No. TD22251, a clutch control rod has been fitted in

place of a clutch cable. On

such cars the free pedal movement "G" (see Fig. E.2) must also be maintained

at 3/4 in. (19 mm.).

This is the extent of the clutch adjustment on the cars from TD22251.

There is no reference in the TD Workshop Manual to the clutch stop

bolt or any adjustment on said bolt.

As people changed the cable

operated clutch to a rod operated clutch in their earlier TDs the

stop pedal stop bolt was never added and the clutch rod began having

problems due to over travel of the pedal.

For a copy of Dave's original file just click here.

(508) 746-6735

email to:Bud@ttalk.info